CFPP Procedure ASTM D6371

Download: AccuracyCFPP.xlsm

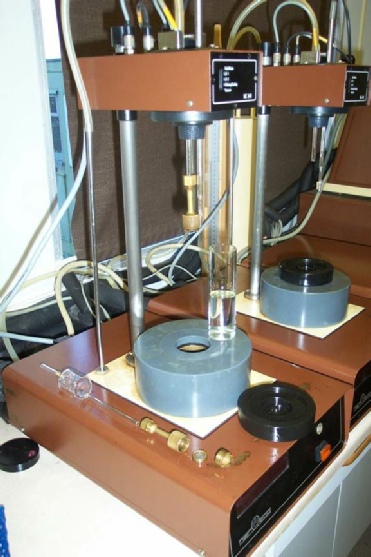

The test tube of fuel is placed in a cold cell at –34°C.

As the fuel cools, at each degree drop, the fuel is pulled through a 45 micron mesh.

The CFPP result is the temperature at which the fuel takes more than one minute to filter.

The UK winter specification is –15°C for Diesel and –12°C for Gas Oil from cloud points of –5 and –2°C.

Central Europe generally blends Diesel to -20 and in Germany –22 °C CFPP from a cloud point of –7°C during the winter season.

The gap between the cloud point and CFPP specification is a significant factor in additive selection and blend formulation.

The quoted Reproducibility (R) is 4.0 and the Repeatability (r) 1.76 for the CFPP test method.

The Excel spreadsheet, AccuracyCFPP.xlsm provides assistance in setting blending targets to take into account the blending process accuracy. A blender should be inside a standard deviation of 1.0 (repeatability 2.8), batch on batch to the same specification. If the variability increases, this may be due to several reasons as follows:-

Blends that are very responsive to the additives (a small dosage <100ppm depresses the CFPP by more than 10°C) can be difficult to control to specification. The cost of CFPP give-away is small in such blends and blending targets can be set with additional safety.

As the refinery feeds and operating modes vary, additives will from time to time fail to match the wax crystallising and give unpredictable responses. This is discussed in the Additives section and monitoring the variance is a useful technique for identifying potential problems with the additive selection.

Mechanical problems with the blender control and dosage systems. Mixing the viscous EVA polymers in to cooler fuels can be an issue with Cold Flow results.