MEASUREMENT OF CETANE NUMBER: IQT

Download: Accuracy.xlsm

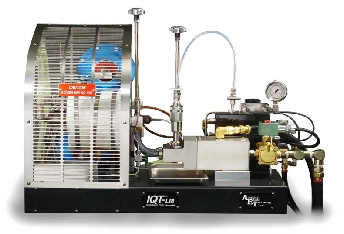

The IQT Instrument is now the most common instrument in use for measuring the cetane number. The replacement of cetane engines with these instruments has greatly improved the blending process in refineries by enabling more data to be generated on component streams and batches of fuel.

The IQT correlates with the cetane number result from a cetane engine and the result is expressed as a ‘Derived’ Cetane Number (dCN). The repeatability and reproducibility have been estimated at 0.76 and 3.2 respectively at 51 cetane number, the specification minimum for most European diesel. The reproducibility statistic indicates 95% of tests on a sample by different laboratories, will fall within a band of 3.2 cetane numbers.

Moderate dosages of 2-EHN increase the cetane by 2-3 numbers and high dosages are used to get up to 5 numbers. It is unusual to target higher responses than 5. Therefore, consideration need to be given to the accuracy of the test procedure when predicting the additive effect and setting dosages.

Measurement Accuracy is usually taken in to account by targeting a cetane number above the specification. Generally, a refinery is focused and practiced in cetane blending to the specification and more skilled than many laboratories in operating the test equipment.

The process accuracy in blending to a target can be estimated from the standard deviation of the batch release results and for a refinery in good control, this can be as low as 0.5 units dCN. This compares favorably to the IQT quoted method standard deviation (σ) of 1.14 (reproducibility of 3.2 divided by 2.8).

A refinery can increase the blending target to increase the certainty a referee laboratory will return a result on-grade or alternatively blend to a tighter target and expect a proportion of the blends to be re-tested as below specification. The download link above, opens an Excel routine to assist with the calculation of the optimum target.