ADDITIVE SELECTION, TECHNICAL SERVICE & LABORATORY SUPPORT

Request document: CFPP Additive Evaluation.pdf

Laboratory support is required for the application of Cold Flow Additives. The download above, details testing protocols to select and maintain the optimum additives for effective treatment of diesel fuel.

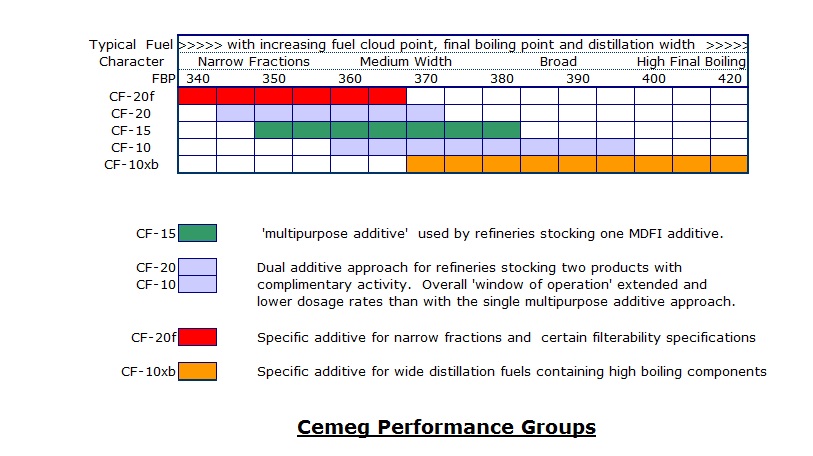

We recommend a refinery approves several additives with neighboring ‘windows of activity’ to treat the full range of fuels produced as the refinery feeds, operating modes and seasons vary the character of diesel batches. Most refineries have sufficient variability in fuel character to require an on-going monitoring programme, checking the match of the additives in use against benchmark products with bordering activity, typically higher and lower Vinyl Acetate contents. This technical service is essential when only one additive can be stored on-site to treat all fuels.

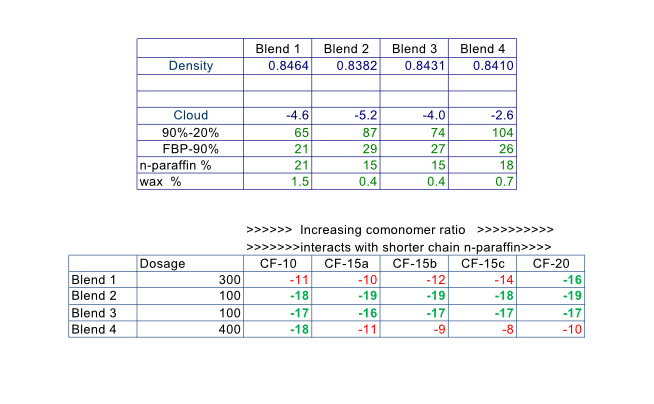

Results from a refinery blending to a -15 CFPP specification experiencing changes in the fuel character between operation modes and feeds. CF-20 is effective in the paraffinic Blend 1 but the more crystalline CF-10 required to react with the broader Blend 4.

Fuels change in character for a number of reasons and the selection of the correct additive to hold on-site requires a detailed knowledge of the refinery operation, both current and future. A common mistake is for samples to be used for additive evaluation that do not reflect the process variability. For example, the best responding additive in samples taken when a refinery is pulling the maximum volume of kerosene for the jet market, will most probably be too specific for samples when high levels of kerosene and higher boiling fractions are being blended to maximise diesel yield.

The following observations can indicate an additive is failing to inter-react correctly with the fuel:-

An unstable CFPP result and regression of the result with time.

High variance in the batch results.

Minimal response with initial dosages and then a large step down to below specification.

Hesitation effects during the CFPP test. Increases in the suction time followed by improvement before a fail several degrees below the hesitation temperature.